Parmatech

ISO 9001 • AS9100D • IATF 16949

Line Card

Parmatech Corporation strives to offer the best solution package to our customers as defined by exceeding their expectations. Solutions include identifying prototyping needs, rapid prototyping, alloy development, metrology assistance, and identification and managing complex secondary operations

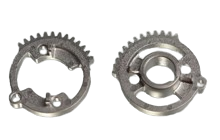

Part Consolidation

- Combine multi-piece machined/assembled sets into one near-net shape

- Lower total cost, fewer suppliers, less scrap and handling

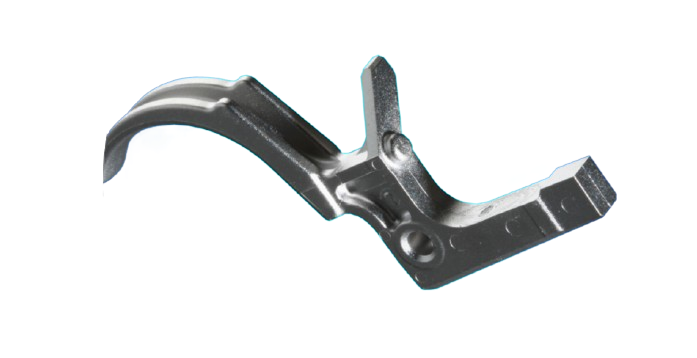

- Complex internal details, undercuts, and branding formed in-tool

Miniaturization

- Small parts, thin walls, micro-features without costly toolpaths

- Typical min walls ~0.3–1.0 mm (design-dependent)

- Fine molded surfaces ~Ra 16–32 µin; cosmetic features achievable

Repeatability @ Scale

- Stable, high-volume output with tight process control

- As-molded tolerances typically ~±0.3–0.5% of nominal

- Post-ops (sizing/machining) used selectively for critical fits

Material Performance

- 316L, 17-4PH, 420/440C, low-alloy steels, Co-Cr, Cu-base

- Soft-magnetic Fe-Ni/Fe-Si; Kovar®/F-15 (CTE-matched)

- Heat treat, passivation/electropolish, coatings, laser marking

| Certifications | AS9100 • ISO 9001 • ITAR |

|---|---|

| Best-fit parts | Small, complex geometries; multi-feature components that benefit from part consolidation |

| Part size / mass | Roughly 0.1–150 g sintered mass typical; envelopes to ~75 mm per side (broader on review) |

| Walls & features | Thin walls ~0.3–1.0 mm typical • Fine details, lettering, undercuts formed in-tool |

| Tolerances / finish | As-molded ~±0.3–0.5% of nominal; selective post-machining for critical fits • Surface finish ~Ra 16–32 µin typical |

| Materials | 316L, 17-4PH, 420/440C, low-alloy steels; Fe-Ni/Fe-Si soft magnetic; Kovar®/F-15; Co-Cr; Cu-base |

| Volumes / MOQs | Prototype (on review) → tens-of-thousands to multi-million per year; strongest value at higher annual volumes |

| Lead times | NPI/tooling ~8–14 weeks typical • Production 4–8 weeks (depends on finishes/material) |

| Secondary ops | Heat treat • Sizing/machining • Grinding/polish • Passivation/electropolish • Coatings • Laser marking • Assembly |

| QA / Documentation | Lot traceability • Inspection to print • FAI/PPAP as required • C of C |

| Markets | Medical instruments & devices • Aerospace/Defense hardware • Industrial & consumer precision components |

A great fit for

- Complex, small metal parts that benefit from consolidating multiple pieces

- High annual volumes needing stable, repeatable output

- Programs requiring cosmetic detail and fine features without heavy machining

Not a fit for…

- Very large / heavy parts or long prismatic shapes

- Ultra-low volumes where new tooling cost can’t amortize

- Commodity hardware or simple turned parts better suited to bar-stock machining

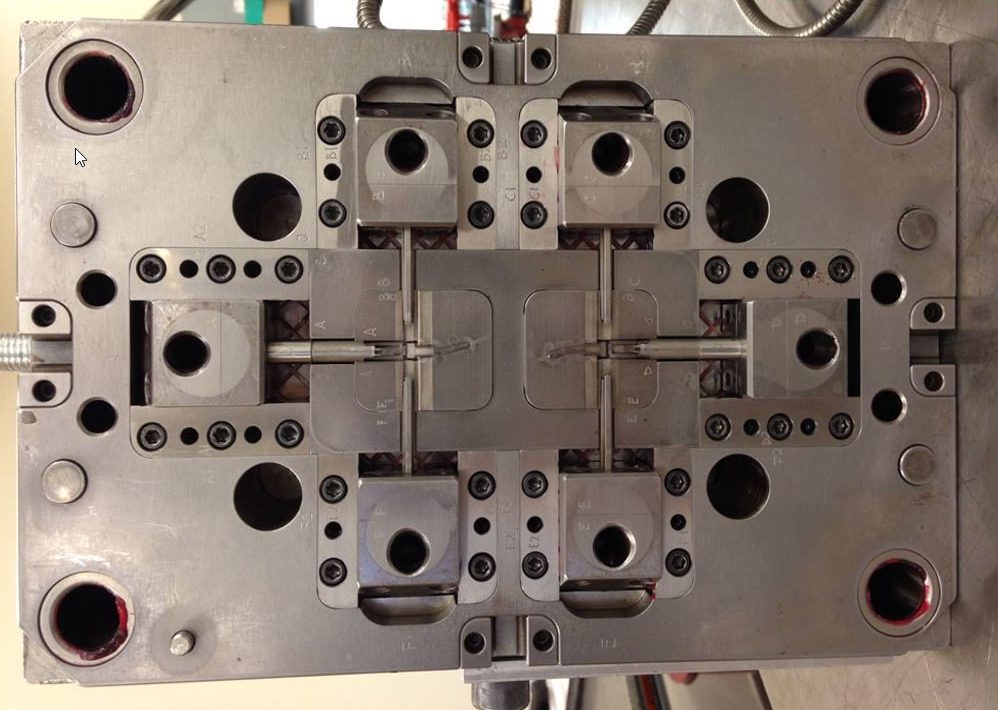

Injection molding presses (small–mid tonnage)

Feedstock mixing/compounding & material prep

Solvent & thermal debinding systems

High-temperature sintering furnaces (vacuum/inert; batch & continuous)

Tooling maintenance (CNC/EDM) & mold room support

Precision sizing/coin presses; secondary machining cells

Finishing cells (tumble/deburr, vibratory, bead blast)

Metrology lab (CMM, vision/optical comparator, hardness)

Laser marking & production packaging

Heat treatment (age harden 17-4, harden 420/440C, stress-relief)

Passivation & electropolishing

Platings/coatings (nickel, gold, tin, black oxide, phosphate, PVD on request)

Shot peen & specialty surface treatments

NDT as required (X-ray/CT, dye penetrant, magnetic particle)

Medical sterilization support via approved partners

Cleanroom/special packaging via approved partners

Medical instruments & devices

Aerospace components

Defense & firearms hardware

Industrial/automation & fluid handling

Consumer products

Electronics & interconnect

Energy, sensors & precision mechanisms

DFM for MIM & part consolidation

Material selection support & prototype sampling

Tooling design coordination & in-house maintenance

Feedstock preparation & injection molding

Solvent/thermal debinding & high-temp sintering

Precision sizing/coin; selective machining & grinding

Surface finishing (deburr, vibratory, bead blast)

Laser marking & full lot traceability

Inspection & documentation (SPC, CMM/vision, FAI/PPAP)

Kitting, light assembly, Kanban/forecast release management

DFM for MIM & part consolidation

Material selection support & prototype sampling

Tooling design coordination & in-house maintenance

Feedstock preparation & injection molding

Solvent/thermal debinding & high-temp sintering

Precision sizing/coin; selective machining & grinding

Surface finishing (deburr, vibratory, bead blast)

Laser marking & full lot traceability

Inspection & documentation (SPC, CMM/vision, FAI/PPAP)

Kitting, light assembly, Kanban/forecast release management

AS9100D

ISO 9001:2015

DFARS Compliant

ITAR

FFL

Contact Us

Tell us a bit about your project and we’ll get back the same business day.

Connect with a Sales Rep

Prefer a direct line? Reach out anytime.

I can get you in direct contact with our engineering team or assist with any additional questions you may have.

Thanks — we’ve got your message.

Expect a response in a couple of hours (business hours). If it’s urgent, call 540-589-7888.