Asteroid Precision

ISO 9001 • ITAR • FFL • SOT

Line Card

We are known for our constant innovation, state of the art technology, highly skilled personnel, and our firm commitment to quality. We have become a preferred supplier for the most well-known OEMs in a range of industries including automotive, medical, military, hydraulic, and industrial.

Centerless Grinding

- Robotic loading; multi-feature grinds in one cycle

- Tight gauging with auto compensation; repeatable < 0.0004"

- Equipment: Cincinnati Milacron, Agathon 255, MPC-600/450/250

ID Grinding

- Okamoto; Studer S122 & S110

- Laser/vision metrology; roundness to 0.00001"

- Leak-critical bores for hydraulics/medical

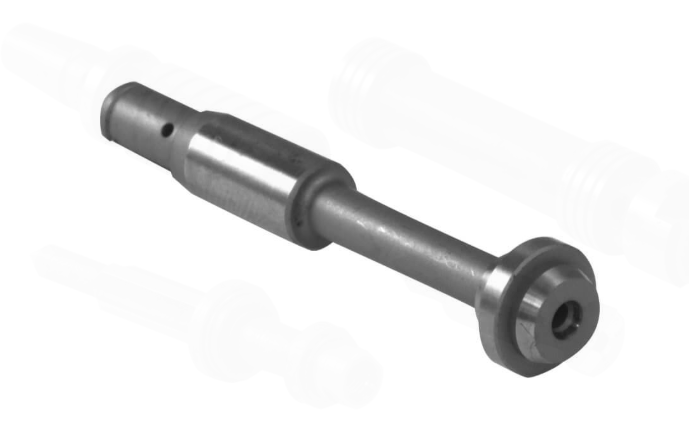

Cylindrical Grinding

- Up to Ø 5" × 30" length; plunge & angle wheels

- Toyoda CNC (GL4/Select G); Studer Favorit

- Automatic dressing; multiple features per setup

Swiss Turning

- Ø 0.04 mm–32 mm; lengths 0.01–6"

- Tolerances to 0.0001"; 11-axis; live tooling; B-axis

- Secondary grinding/honing managed for parts-complete

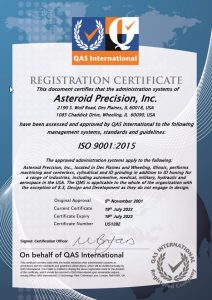

| Certifications | ISO 9001:2015 • ITAR • FFL Type 7 • SOT |

|---|---|

| Core processes | Swiss turning • Milling • Precision grinding (centerless, cylindrical, ID) • Honing |

| Swiss turning window | Ø 0.04 mm–32 mm (to 1.25") • lengths 0.01–6" • tolerances to ±0.0001" |

| Grinding window | Up to Ø 5" × 30" length • auto length compensation & gauging capable of < 0.0004" • auto dressing • robotic ops |

| Representative equipment | Cincinnati Milacron; Agathon 255 (robotic); MPC-600/450/250 • Toyoda GL4/Select G; Studer Favorit • Okamoto; Studer S122/S110 • Engis multi-stations & SPM (honing) |

| Quality & metrology | OGP Vision (laser) • MMQ 400 • CS-3200 • MicroVu • geometric gauging to 0.00001" roundness • laser micrometers repeatability 0.00002" |

| Documentation | PPAP (Level 3) • SPC • FAI • Certificate of Compliance • staged inspections (FAI, in-process, random sampling, final) |

| Industries | Automotive • Firearms & Defense • Hydraulics • Medical |

| Locations | Des Plaines, IL • Wheeling, IL |

A great fit for

- Tight-tolerance parts requiring centerless/ID/cylindrical grinding with gauged repeatability

- Swiss-turned micro/miniature components with downstream grinding/honing

- Programs needing PPAP/FAI, SPC, and documented inspection flow

Not a fit for…

- Same-day emergency builds

- Large prismatic fabrications or sheet-metal assemblies

- Non-domestic sourcing requests

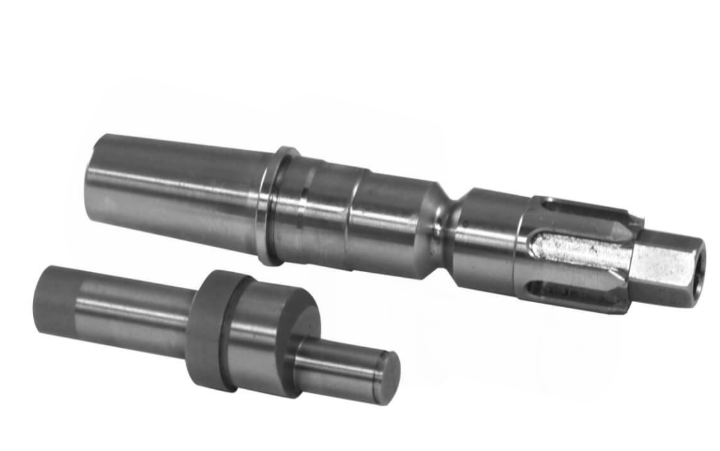

Swiss turning (Ø 0.04 mm–32 mm / to 1.25″, lengths 0.01″–6″, to ±0.0001″)

Multi-axis mills & mill-turns (Fanuc Robodrill, Nakamura, Brother, Yam Seiki, etc.)

Centerless grinding (Cincinnati Milacron, Agathon 255 robotic, MPC-600/450/250)

Cylindrical grinding (Toyoda GL4 / Select G, Studer Favorit)

ID grinding (Okamoto; Studer S122/S110)

Honing (Engis multi-stations, Engis SPM)

Metrology (OGP Vision/laser, MMQ 400, CS-3200, MicroVu; laser mic repeatability ~0.00002″)

Heat treat (through/induction/age-harden, stress-relief)

Coatings & plating (nitriding, phosphate, black oxide, nickel, etc.)

Surface finishing (tumble, deburr, bead blast) beyond in-house as needed

Specialty testing/NDT via approved partners (X-ray/CT, dye penetrant, mag particle)

Marking/packaging per spec (incl. labeling, protective packaging)

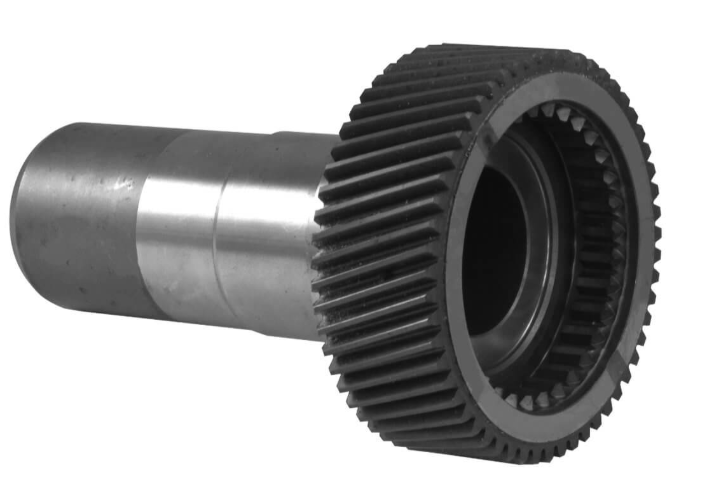

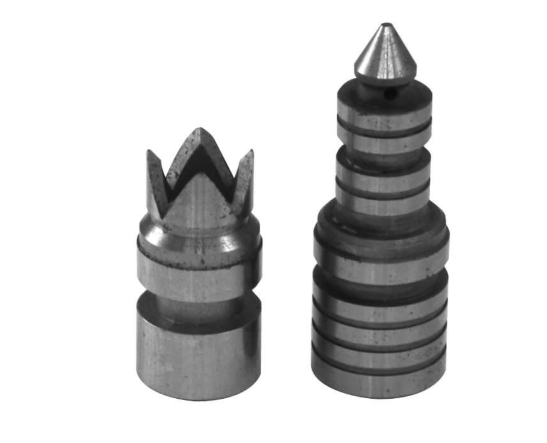

Automotive (manifolds, gears, spools, plungers, pins, valves)

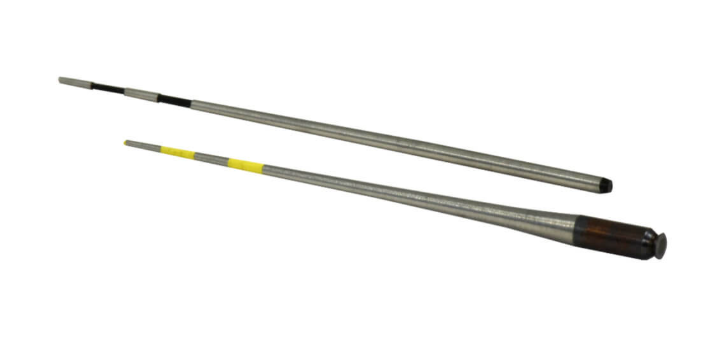

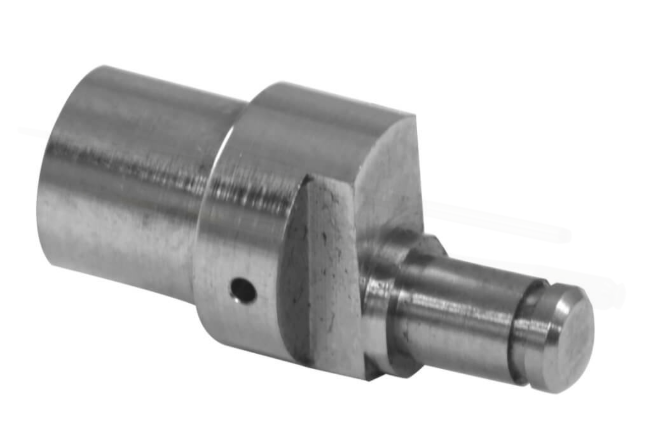

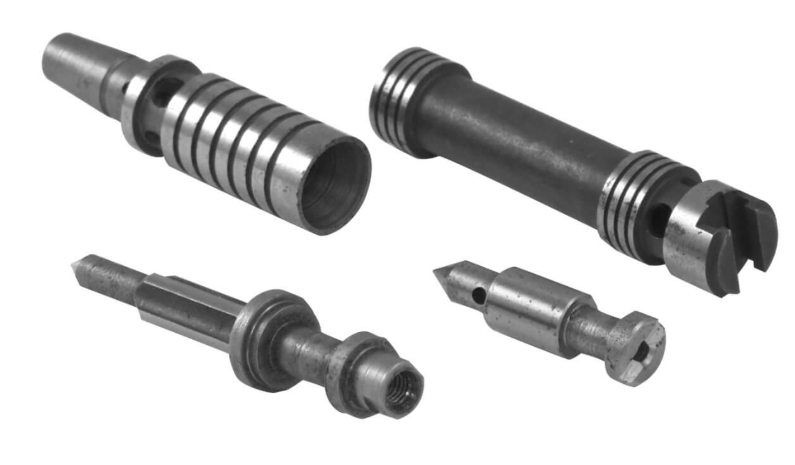

Firearms & Defense (bolts, carriers, gas keys, ejectors, barrel extensions, pins, LPKs)

Hydraulics/Pneumatics (poppets, sleeves, valves, spools, shafts, housings)

Medical & Dental (motor housings, probes, picks, shafts, burrs, pins, chambers)

Industrial/General OEM components

Swiss turning (miniature/tight-tolerance; live tooling, B-axis, up to 11 axes)

Precision grinding (centerless, cylindrical, ID) with auto gauging/compensation

Milling and mill-turn machining; secondary ops (drill, mill, broach, coin)

Honing to final geometry and finish

Quality documentation & control (FAI, PPAP L3, SPC, staged inspections)

Lot traceability, C of C; production packaging and kitting

ISO 9001:2015

ITAR

FFL

SOT

Contact Us

Tell us a bit about your project and we’ll get back the same business day.

Connect with a Sales Rep

Prefer a direct line? Reach out anytime.

I can get you in direct contact with our engineering team or assist with any additional questions you may have.

Thanks — we’ve got your message.

Expect a response in a couple of hours (business hours). If it’s urgent, call 540-589-7888.