AGF Defcom

ISO 9001 • ITAR • FFL • SOT

We are known for our constant innovation, state of the art technology, highly skilled personnel, and our firm commitment to quality. We have become a preferred supplier for the most well-known OEMs in a range of industries including automotive, medical, military, hydraulic, and industrial.

DfAM Review

- Design for additive: wall thickness, channels, supports, orientation

- Alloy selection: 17-4, 316L, Ti-6Al-4V, Inconel 718

- Tolerance strategy: as-printed vs post-machined

Build & Depowder

- EOS-class DMLS; typical layer 20–60 µm

- Common build 250×250×325 mm; larger on review

- Depowdering + EDM part removal from build plate

Heat Treat / Stress-Relieve

- Stress-relief per alloy and geometry

- Heat treat for strength/hardness targets (program-dependent)

- Media blast/tumble prep for finishing

5-Axis CNC Finish & Inspect

- Critical bores, threads, sealing faces to print

- 5-axis contouring; fixturing for thin-wall features

- Final inspection & documentation (FAI/C of C as required)

| Certifications | ISO 9001 • ITAR • FFL/SOT |

|---|---|

| Primary process | Direct Metal Laser Sintering (DMLS) with EOS-class systems |

| Common build volume | 250×250×325 mm typical; larger formats on review |

| Layer thickness | ≈20–60 µm, per alloy/feature mix |

| Feature guidance | Min wall ≈0.5–0.8 mm; channels ≥0.8–1.0 mm; overhangs per support strategy |

| Alloys | 17-4 PH • 316L • Ti-6Al-4V • Inconel 718 (others on request) |

| As-printed tolerances | Nominal ±0.003–0.005" on small features; scale with size (finals per print after CNC) |

| Surface finish | As-printed ≈200–400 µin Ra; machined faces to ≤32 µin Ra (finer on request) |

| Post-processing | Depowder • EDM part removal • Stress-relieve • Heat treat • Media blast/tumble • 5-axis CNC finish |

| Inspection & docs | FAI • Certificate of Compliance • Traceability per program requirements |

| Volumes | Prototype → bridge → production (repeat programs supported) |

| Industries | Firearms/Defense • Industrial • Energy • R&D |

A great fit for

- Lightweighting, part consolidation, internal channels or lattice

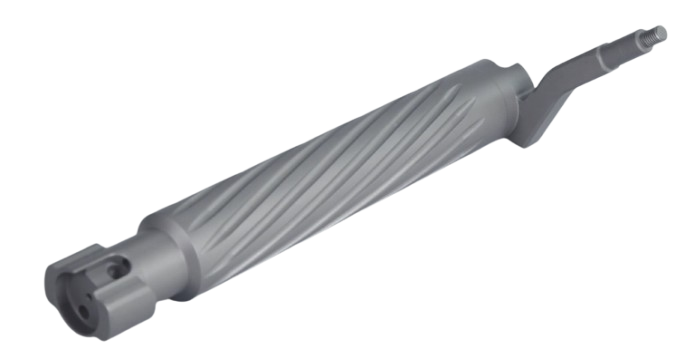

- Firearms/Defense components needing strength + tight machined faces

- Prototype → bridge → production with repeatable documentation

Not a fit for…

- Large flat cosmetic panels needing mirror finishes without machining

- Ultra-thin walls < 0.3 mm across long spans

- Commodity parts better served by casting or sheet-metal

(DfAM)

Geometry & walls: min wall/feature sizes, fillets, overhangs, ribs, self-supporting angles.

Supports & orientation: fewest supports, easy removal, best surface on critical faces, shortest build height.

Channels/holes: printable diameters, escape holes for powder, straight vs. helical, post-reaming plan.

Tolerance plan: what stays “as-printed” vs. what gets CNC finished (bores, threads, sealing faces, datums).

Material & heat treat: 17-4 / 316L / Ti-6Al-4V / 718 choices, stress-relief/HIP needs, final properties.

Cost drivers: part height, support volume, nesting, cycle time, post-ops.

Aim for ≥45° self-supporting angles where possible.

Keep min walls ~0.5–0.8 mm (thicker for tall spans).

Provide powder-escape paths for internal cavities.

Call out machined features (Ø, threads, sealing faces) on the print.

Shorter build height = cheaper/faster (when orientation allows).

Recommended orientation & support strategy (with critical-face protection).

Feature tweaks (radii, wall/slot sizes, channel diameters) to print reliably.

A simple post-process map: stress-relieve/HIP → blast → 5-axis CNC → inspect (FAI/C of C).

Production metal DMLS systems (EOS-class), dedicated depowdering, EDM build-plate removal

5-axis CNC mills for post-machining of additively manufactured parts (tight-tolerance bores, threads, sealing faces)

Workholding/fixturing for thin-wall AM geometries; rotary trunnion setups for multi-face finishing

Inspection: precision hand metrology; program-level documentation for FAI/C of C and traceability

Shop support: blasting/tumble for surface prep; saws, tooling, and setup equipment

Heat treat & stress-relief per alloy (e.g., 17-4 H900/H1025; Ti-6Al-4V; Inconel 718)

HIP (hot isostatic pressing) for density/mechanical properties when required

Coatings/finishes via approved partners (passivation, black oxide/phosphate, nitriding/PVD as specified)

NDT/testing on request (e.g., dye penetrant, mag particle, CT/X-ray through partners)

Packaging/labeling to spec; certification coordination

Firearms & Defense (additive components with CNC-finished critical features)

Industrial & Energy (light-weighting, internal channels, consolidated assemblies)

R&D/Pre-production (prototype → bridge → production pathways)

General OEM applications needing complex geometries and rapid turn

DfAM review (orientation, support strategy, wall/channel guidance, tolerance plan)

DMLS build, depowdering, part removal (EDM), surface prep for finishing

5-axis CNC machining of AM parts (bores, threads, sealing faces, datum features)

Feature validation & documentation (FAI, C of C, traceability per program)

Program management from prototype through repeat production (ISO 9001 • ITAR • FFL/SOT)

ISO 9001:2015

ITAR

FFL

SOT

Accordion Content

Contact Us

Tell us a bit about your project and we’ll get back the same business day.

Connect with a Sales Rep

Prefer a direct line? Reach out anytime.

I can get you in direct contact with our engineering team or assist with any additional questions you may have.

Thanks — we’ve got your message.

Expect a response in a couple of hours (business hours). If it’s urgent, call 540-589-7888.