Judson Smith

ISO 9001 • AS9100D • ITAR • FDA Registered

Line Card

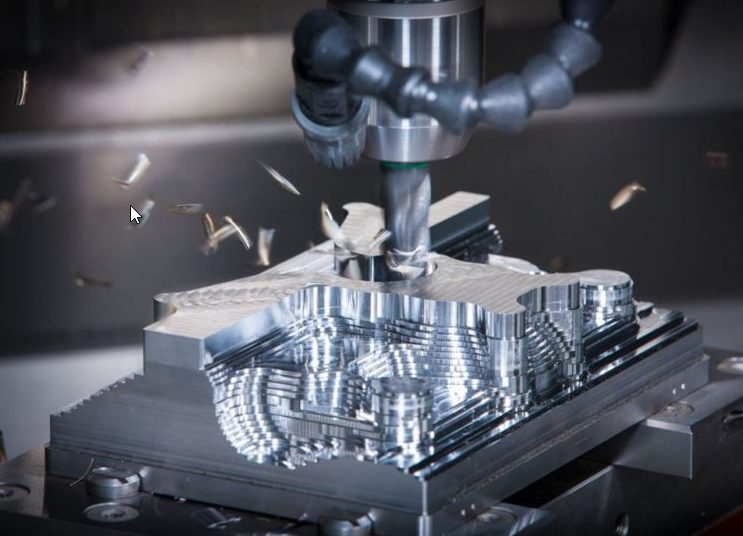

Make (CNC & Swiss)

- 5-axis CNC milling; vertical & horizontal cells (FMS) for lights-out

- 2- & 5-axis turning; 4-axis Swiss for small/complex parts

- Materials: stainless, titanium, Co-Cr, aluminum, plastics, nickel alloys

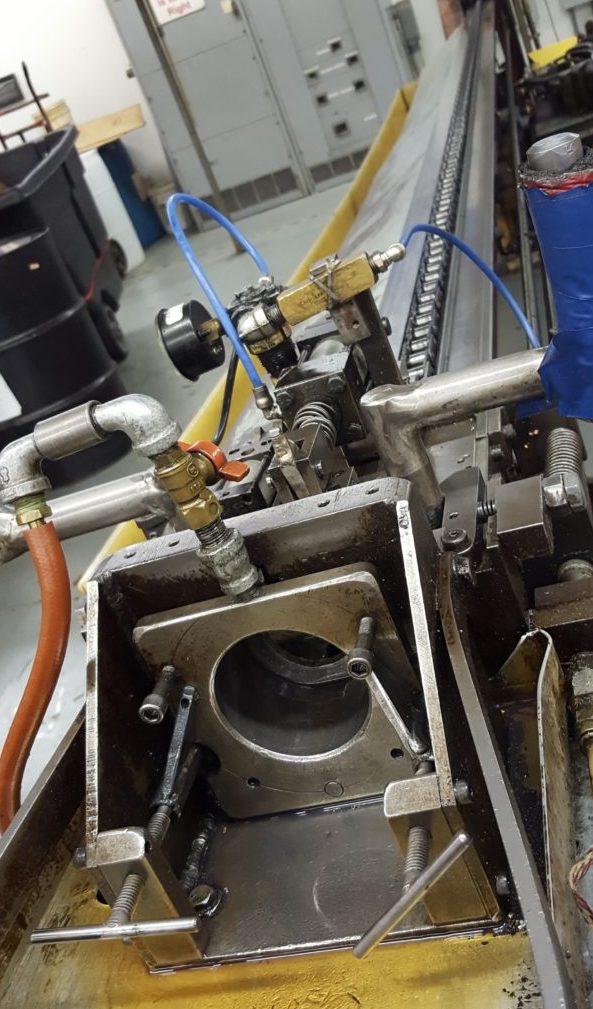

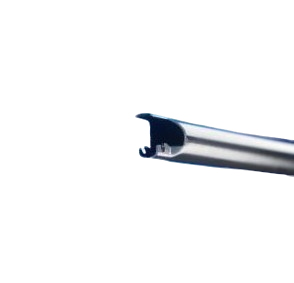

Form (Tube Fabrication)

- Laser/ECM/shear/saw cutting; bending, swaging, punching

- Notch, flare, bead, slot, dimple, lance; reduce/expand; special machining

- Shapes: round/rect/square/custom; OD ~.010″–.750″; wall ~.001″–.065″

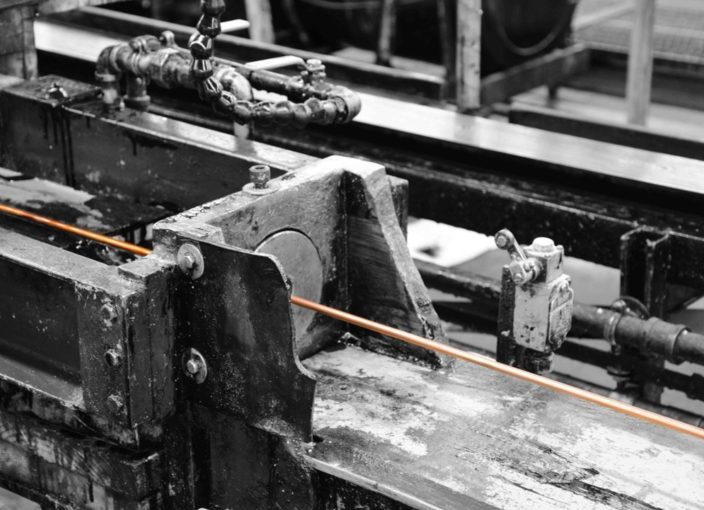

Draw (Custom Tubing)

- Non-ferrous seamless or welded & drawn; round/rect/square/custom

- Improved finish & accuracy; flexible size/lead-time; coils or lengths

- Program support from prototype → production

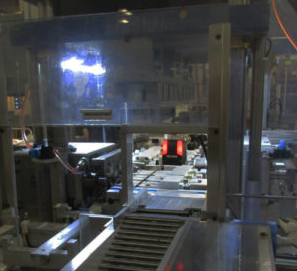

Assemble (Weld/EDM/Laser)

- Wire EDM for precision tooling/features; fiber-laser cut/weld/mark

- TIG & laser welded assemblies; serialization & packaging

- QA: CMM, vision, comparators; validations & traceability

| Certifications | ISO 9001:2015 • AS9100D • FDA Registered • ITAR Compliant |

|---|---|

| Core machining | 5-axis CNC milling; vertical & horizontal mills with FMS • 2- & 5-axis turning • 4-axis Swiss turning • Full CAD/CAM & tool-room support |

| Tube fabrication | Laser/ECM/shear/saw cutting • Bending, swaging, punching • Notching, flaring, beading, slotting, dimpling, lancing • Reduce/expand • Special machining • Shapes: round/rect/square/custom • Size guide: OD ~.010″–.750″ • wall ~.001″–.065″ |

| Tube drawing | Non-ferrous seamless or welded & drawn; custom sizes; round/rect/square/custom shapes; improved finish & accuracy; coil or straight lengths |

| Wire EDM & Laser | Wire EDM for complex profiles & tooling • Fiber-laser cutting, precision laser welding, high-contrast laser marking |

| Assemblies | TIG & laser welded assemblies • Finished parts & assemblies • Serialization/marking • Packaging |

| Materials | Stainless steels • Titanium • Cobalt-chrome • Aluminum • Plastics • Brass/copper • Nickel alloys (incl. Monel, 42/52, Kovar) |

| Finishing | Heat treat (managed) • Bead blast • Bright dip • Tumbling • Cleaning/degreasing • Passivation • Electropolish |

| Quality | CMM • OGP SmartScope vision • Optical comparators • NDT (through partners) • Validation expertise • GMP-aligned practices • JIT/stocking options |

| Industries | Medical devices & orthopedic • Aerospace/Defense • Automotive • Electronics • Industrial/OEM |

| Scales | Prototype → short-run → production; three-shift capability; lights-out FMS for repeatability & cost |

A great fit for

- PPAP/FAI-driven programs (auto/industrial/defense)

- Tight cycle-life/load requirements with DFM collaboration

- Multi-family spring programs (shared tooling strategies)

Not a fit for…

- Catalog/no-print commodity purchases

- Non-domestic sourcing requests

- Same-day emergency builds

5-axis CNC machining centers; vertical & horizontal mills with FMS (lights-out capable)

CNC lathes (2- & 5-axis); Swiss turning (4-axis)

Tube fab equipment: fiber-laser cutters, ECM, precision saw/shear, tube benders, swagers, punch presses, end-formers

Tube drawing benches & tooling (non-ferrous; seamless and welded-&-drawn)

Wire EDM machines

Laser welding systems; laser cutting & laser marking

TIG welding stations with dedicated fixtures

Metrology: CMM, OGP vision/SmartScope, optical comparators, calibrated gages

Cleaning/degreasing, bead blast/tumble; CAD/CAM and tool-room support

Heat treat (solution/age, hardening) and stress-relief per alloy

Plating/coatings & surface finishing per spec (passivation, electropolish, anodize/PVD as required)

NDT/testing via approved partners (dye penetrant, mag particle, X-ray/CT)

Specialty packaging/labeling & documentation coordination

Medical devices & orthopedic instruments/implants

Aerospace & Defense components and assemblies

Industrial/OEM and Electronics

Automotive (precision machined & tubular parts)

CNC milling (3–5 axis), turning, Swiss turning; fixtures & custom tooling

Tube fabrication: cut (laser/ECM/saw/shear), bend, swage, punch; notch/flare/bead/slot/dimple/lance; reduce/expand; special end-forms

Tube drawing: non-ferrous, round/rect/square/custom shapes; coils or straight lengths

Wire EDM for complex profiles & tooling

Laser cutting, laser/TIG welding, laser marking; serialized/marked parts

Welded assemblies & sub-assemblies; finishing & packaging

Quality & docs: CMM/vision inspection, FAI, C of C, traceability; validation support; JIT/stocking options

Program management from prototype → production, leveraging FMS for repeatability and cost

ISO 9001:2015

AS9100D

FDA Registered

ITAR

Contact Us

Tell us a bit about your project and we’ll get back the same business day.

Connect with a Sales Rep

Prefer a direct line? Reach out anytime.

I can get you in direct contact with our engineering team or assist with any additional questions you may have.

Thanks — we’ve got your message.

Expect a response in a couple of hours (business hours). If it’s urgent, call 540-589-7888.