Precision Form

ISO 9001 • ITAR

Line Card

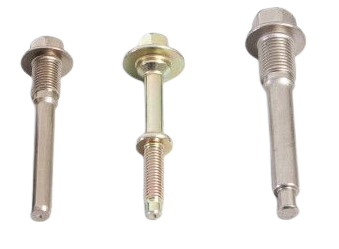

As a market leader in custom small parts, PrecisionForm clearly believes in the efficiency and high production rates afforded by precision cold forming. However, we know it’s our wide array of machining and technical services that together meet our customers’ demands.

From initial part design through final production we work hand-in-hand to adhere to your production objectives-in many cases even producing prototypes in order to assure total customer satisfaction.

CNC Swiss — complex/tight tolerance

- Bars ~0.040–1.50 in (1–38 mm); cross/axial holes, slots, fine threads

- Typical tol ±0.0005 in (tighter on review)

- Great for prototypes → early production; families with design iteration

Multi-Spindle — cost at volume

- High part rate with multiple tools in cycle; strong COGS for mid/high volumes

- Inline ops: drill, mill flats/slots, cutoff forms, thread roll/cut

- Ideal when annual usage grows beyond Swiss economics

Cold Heading (up to 6-die) — near-net shape

- Wire ~0.060–0.625 in typical; progressive forming for heads, collars, ribs

- Best value at 25k+ pcs/run; coin/size/grind for precision surfaces

- Huge throughput; material savings vs. full-turning

Finish Machining / Grinding

- Critical ODs/IDs, grooves, faces; secondary drill/slot/broach

- Thread rolling/cutting; centerless/OD grind

- Blends headed + machined features to print

| Certifications | ISO 9001 |

|---|---|

| Processes | CNC Swiss • Multi-spindle automatic • Cold heading (up to 6-die) • Finish machining/grinding • Thread rolling/cutting • Broach/slot/mill |

| Size ranges | Swiss/multi-spindle bars ~0.040–1.50 in (1–38 mm) typical • Cold-heading wire ~0.060–0.625 in typical |

| Tolerances | Machining ±0.0005 in common (tighter on review) • Heading ±0.002–0.004 in typical; coin/size/grind for criticals |

| Materials | Carbon/alloy steels (10xx, 11xx, 12L14, 41xx) • Stainless 300/400 • Brass/bronze • Aluminum • Copper • Others on review |

| Volumes | Prototype → million+ (machined) • Best value for heading at ≥25k pcs/run |

| Lead times | NPI 2–4 wks • Production 4–8 wks (machined); 8–12+ wks typical for headed programs incl. tooling |

| Finishing | Heat treat • Passivation • Plating/coatings • Shot-peen • Cleaning/packaging • Laser/ink marking |

| QA / Docs | In-process SPC • CMM/vision • PPAP L1–L3 • FAI • C of C • Lot traceability |

A great fit for

- Programs scaling from prototype to volume (cost down path: Swiss → multi-spindle/heading)

- Parts with thread, cross-hole, groove, flat/slot features

- High-volume fasteners, pins, fittings, bushings needing throughput

Not a fit for…

- One-off jobs requiring same-day turn

- Ultra-large diameters/lengths beyond bar/wire ranges

- Requests that prohibit domestic manufacturing

Cold forming presses: single-stroke to 5-die multi-blow (parts ~1.5×3 mm to 25.4×200 mm)

Multi-spindle screw machines up to 57 mm

Turn-mill machining centers up to 65 mm

Swiss CNC lathes to 20 mm bar (Citizen Cincom A20 Type VII, C16 IX)

Conventional CNC lathes up to 88 mm

Horizontal & vertical machining centers (Doosan HP4000 II, Mori Seiki SH-500, MV Junior; Haas UMC-500 5-axis)

EuroTech Trofeo Elite 8465 SY2 (twin turret/spindle, bar feeders) and Rapido B436-Y2 (twin turret/spindle)

(2) Miyano LZ-01R lathes; Miyano LM-II lathe

Managed 3rd-party services for vendor consolidation (approved suppliers)

Heat treat beyond in-house aluminum (e.g., alloy/SS hardening, stress-relief)

Plating/coatings (e.g., zinc, nickel, phosphate, black oxide), passivation/anodize as needed

NDT / lab testing as required per program (material, hardness, coating thickness)

Specialty finishes and protective packaging to print

Commercial fasteners

Industrial

Aerospace fasteners

Firearms

Automotive

Specialty products

Medical

Flow control

Engineering DFM/cost-route selection; prototype capability prior to production

Toolmaking & gage production on site; tooling repair & replacement

Cold forming (single-stroke to 5-die multi-blow)

Rotary transfer machining; CNC turning/milling; Swiss turning to 20 mm; multi-spindle to 57 mm

Secondary ops: high-speed flat-die thread rolling, roll forming, precision punch

Parts cleaning & finishing: tumble degreasing; bulk rotary/vertical wash; burnishing; vibratory bowl finishing

Aluminum heat treatment in-house

Full quality inspection & gage lab; material testing & analysis

Assembly and kitting; critical 3rd-party service management for turnkey delivery

ISO 9001:2015

ISO 14001 Compliant

ITAR

Contact Us

Tell us a bit about your project and we’ll get back the same business day.

Connect with a Sales Rep

Prefer a direct line? Reach out anytime.

I can get you in direct contact with our engineering team or assist with any additional questions you may have.

Thanks — we’ve got your message.

Expect a response in a couple of hours (business hours). If it’s urgent, call 540-589-7888.