Tucker Industries

IATF 16949 • ISO 14001 • Veteran-Owned

Line Card

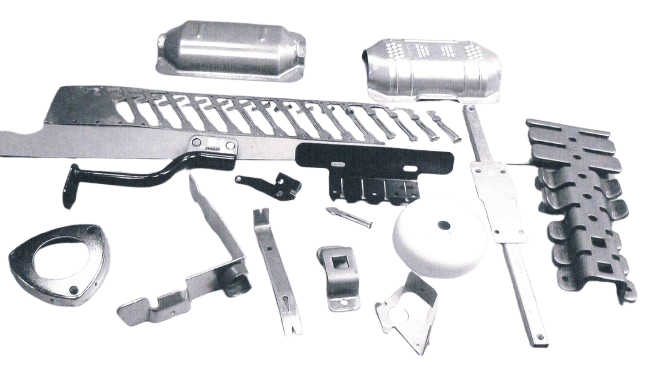

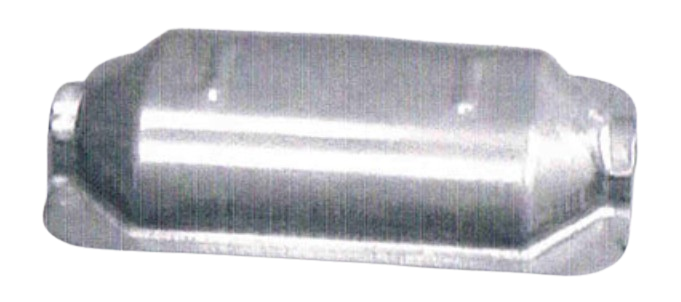

Tucker Industries' metal stampings products and services are designed to meet the diverse needs of its customers in various industries, including automotive, aerospace, agriculture, and consumer products. The company has built a reputation for providing innovative solutions, exceptional quality, and outstanding customer service.

Progressive Stamping

- Presses to 600 tons; beds to 9'×4'; to 48" feed width

- High speed; one setup/operation/inspection for cost & repeatability

- In-die tapping/assembly to eliminate secondary ops

Fabrication (Turret/Brake)

- Amada King II/Queen turret presses; Amada RG-80/RG-125 brakes

- Prototype & low-volume; sheets to 4'×8'; including pre-painted stock

- Quick changes with low tooling cost

Robotic Welding

- Accuracy from robust dedicated fixtures; frequent maintenance

- Check/test fixtures near cell to confirm fit & function

- Combines multiple parts to finished assemblies

Finish & Kitting

- Deburr, wash, plating, e-coat/powder coat; packaging & labeling

- Kitting/bundling/customization; JIT/EDI/barcoding

- Vendor consolidation with managed outside services

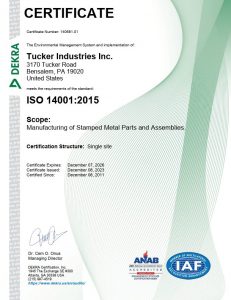

| Certifications | IATF 16949 • ISO 14001 • Veteran-owned |

|---|---|

| Stamping capacity | Presses up to 600 tons • beds to 9′×4′ • feed width to 48″ • press speed up to 1,200 spm |

| Large press area | 440-ton Stamtec (4′×9′) with ¼″×24″ servo feed • 330-ton Komatsu (4′×8′) with ¼″×24″ feeder |

| Fabrication | Amada King II / Queen turret presses • Amada RG-80 / RG-125 press brakes • up to 4′×8′ sheets; pre-painted OK |

| Prototype / short-run | Press brake 10′ • Shear ¼″×10′ • Trumpf Lasercat 2603E (2.6 kW) 5′×10′ bed |

| Die room | Wire EDM • CNC machining center • Bridgeports • surface & Blanchard grinders • radial drills • band saws • lathes |

| Finishing | 24′ inline high-speed deburr • 10 CF circular deburr • 11-ga × 24″ edge deburr • 20-roll straighteners • sandblast • multi-stage washer |

| Materials | Carbon & alloy steels • Stainless • Aluminum • Copper & copper alloys • Pre-painted coil/sheet |

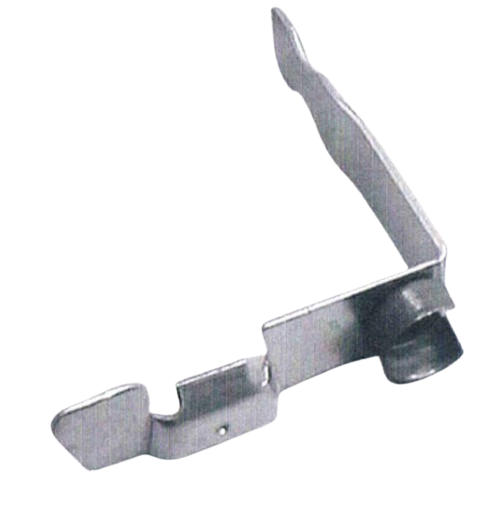

| Value-added | In-die tapping/assembly • Robotic/manual welding • Riveting • Coining • Tapping • Polishing • Heat treat • Plating (zinc, nickel, phosphate, black oxide) • E-coat • Powder coat • Assembly • Kitting/bundling • Packaging/labeling |

| Quality | CMM • calibrated gages & fixtures • Preventive QC • Lean/CQI • VAVE • EDI, barcoding, JIT scheduling |

| Industries | Auto/Truck • Lighting • Motorcycle • Electrical distribution • Power & hand tools • Decking hardware/brackets • General industrial |

A great fit for

- High-volume progressive stampings with in-die tapping/assembly

- Programs needing robotic welding into finished assemblies

- Prototype/low-volume sheet parts (4′×8′) transitioning to tooling

Not a fit for…

- Ultra-large fabrications beyond press/turret/brake envelope

- Same-day emergency builds

- Non-domestic sourcing requests

- ~60 stamping presses up to 600 tons; beds to 9′ × 4′; feeders to 48″ wide (advance to 36″); reels/straighteners/cradles to 10,000 lb / 48″

- Large press area: 440-ton Stamtec (4′ × 9′) with ¼″ × 24″ servo feed; 330-ton Komatsu (4′ × 8′) with ¼″ × 24″ feeder

- Fabrication: Amada King II / Queen turret presses; Amada RG-80 / RG-125 press brakes; sheets to 4′ × 8′ (pre-painted OK)

- Prototype/short-run: press brake 10′; shear ¼″ × 10′; Trumpf Lasercat 2603E (2.6 kW, 5′ × 10′ bed)

- Finishing cells: 24′ inline high-speed deburr; 10 CF circular deburr; 11-ga × 24″ edge deburr; 20-roll straighteners; sandblast; multi-stage washer

- Die room: wire EDM; CNC machining center; Bridgeports; surface & Blanchard grinders; radial drills; band saws; lathes

- Welding: multiple robotic cells + manual MIG with dedicated/check fixtures

Heat treat (managed with approved partners)

Plating/coatings: zinc, nickel, phosphate, black oxide, plus e-coat and powder coat

Additional finishing as required (tumble/deburr, polishing)

Packaging/labeling to spec; certification/testing coordination per program needs

Heavy & light truck (cab/chassis/engine)

Automotive (interior, seat frame, engine)

Motorcycle (engine/frame/brakes)

Lighting (overhead fixtures, 2′–8′ lengths)

Electrical distribution (small/medium/large stampings)

Power & hand tools

Decking hardware, brackets, kitting

General industrial

Progressive die stamping; compound/tandem and secondary-operation dies

Fabrication (turret punch & press-brake forming); laser for prototypes/low volume

Robotic welding and manual MIG; spot welding; riveting, tapping, coining, hardware insertion

Assemblies & sub-assemblies; kitting/bundling; custom packaging; EDI/barcoding, JIT logistics

Tool & die: in-house design/build/maintenance (with Superior Tool & Die); engineering changes

Quality: CMM & calibrated gages/fixtures; Preventive QC; Lean/CQI; VAVE; RPPM monitoring

On-line finishing: degrease/wash, burnish, vibratory/circular/edge deburr, straightening, sandblast, multi-stage parts washer

IATF 16949:2016

ISO 14001:2015

Contact Us

Tell us a bit about your project and we’ll get back the same business day.

Connect with a Sales Rep

Prefer a direct line? Reach out anytime.

I can get you in direct contact with our engineering team or assist with any additional questions you may have.

Thanks — we’ve got your message.

Expect a response in a couple of hours (business hours). If it’s urgent, call 540-589-7888.