Swiss Automation

ISO 9001 • ISO 13485

Line Card

We are the largest manufacturers of Precision Turned Components in the US, with over 150 of the finest dual-spindle lathes in the world, many with up to 12 axis of cutting capability.

We are also the country’s largest holders of both Citizen and Tornos-Bechler DECO CNC Swiss-Type Screw Machines in addition to a wide array of Star, Miyano, Hardinge, and Eurotech machines.

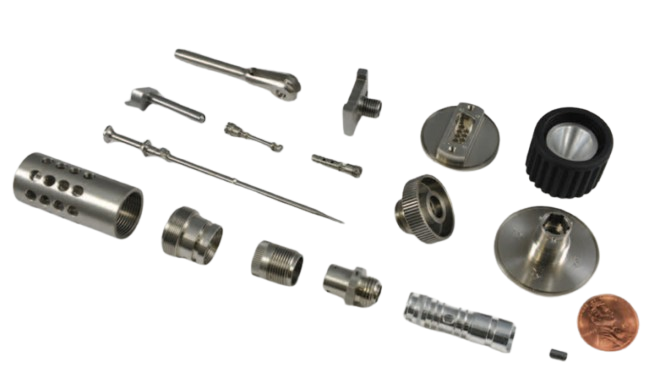

Medical

- ISO 13485 programs for implants & instruments

- Bar Ø 0.040–1.50 in (1–38 mm); typical tol ±0.0005 in, to ±0.0001 in on review

- Thread whirling (incl. bone-type), cross/axial holes, fine milling

- Materials: 316L, 17-4, 455/465, Ti-6Al-4V, Co-Cr, PEEK/Ultem, nitinol

- Process controls: SPC, CMM/vision, lot traceability & device records

- Finishing: passivation (ASTM A967), electropolish, UDI laser marking, packaging

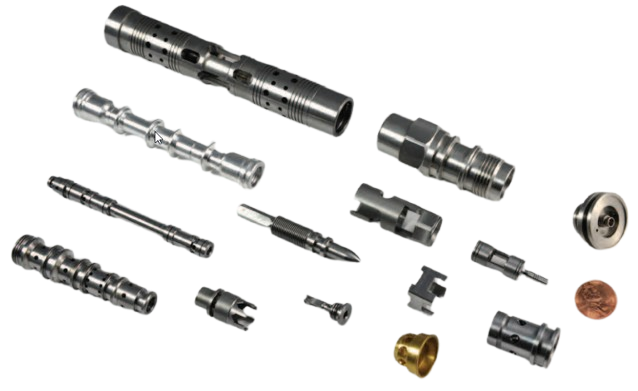

Aerospace & Defense

- Precision turned parts for avionics, connectors, jet-engine sub-components

- Zero-error/zero-defect programs; burr-free, high surface quality

- Complex geometries: threads, deep/cross drilling, milled features

- Materials: stainless, titanium, nickel alloys, aluminum, brass

- Documentation and traceability per program needs

Hydraulics / Pneumatic

- Valve components: spools, sleeves, poppets, fittings

- Tight concentricity, leak-critical edges, controlled surface finish

- Cross-holes, grooves, threads; deburr/edge-break for clean assembly

- Materials: stainless, alloy/carbon steels, brass, aluminum

- Prototype to high-volume runs on 24/7 schedule

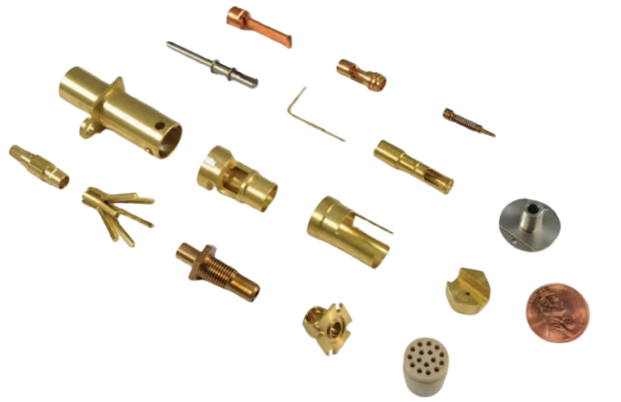

Electronics / Other

- Micro to large families; quick turn and single set-ups supported

- Connectors, pins, housings, precision hardware

- Materials: brass, copper, stainless, aluminum, plastics

- Scalable production: prototype → million+ with consolidated sourcing

| Certifications | ISO 13485:2016 (fully certified) • ISO 9001 • ITAR |

|---|---|

| Bar diameters | Swiss bar 0.040–1.50 in (1–38 mm) typical |

| Part envelope | Outside diameter capacity up to 2.75 in (70 mm) on multi-turret lathes • Swiss turned lengths to ~12 in • Complex milled features, cross/axial holes, thread whirling |

| Tolerance / finish | As tight as ±0.0001 in (typical medical features ±0.0005 in / ±0.013 mm) • Surface finish Ra 16–32 µin typical; finer on request |

| Equipment | ~180 Swiss-type screw machines plus multi-turret lathes • Capability for prototypes, short lead times, quick turnarounds, single set-ups |

| Materials | Any grade of Stainless • Titanium • Brass • Nickel • Copper • Mil-Spec steels • Carbon steel • Alloy steel • Aluminum • Bronze • PEEK / engineering plastics • Customer-supplied materials • Others as required |

| Production scale | Prototype → million+ runs • Small/medium/large lots in a 24/7 production schedule • Large-scale capacity for consolidated sourcing |

| Lead times | NPI 2–4 weeks • Production 4–8 weeks (expedites when releases permit) |

| Process control | Tightly controlled, continuously reviewed processes • Parts free of burrs/slivers • Zero-error/zero-defect programs for Aerospace & Defense applications |

| Finishing | Clean • Passivate (ASTM A967) • Electropolish • Laser mark (UDI) • Packaging |

| Inspection | In-process SPC • CMM/vision • Certifications & lot traceability with device records |

| Markets served |

|

| Heritage | 50+ years delivering best-in-class parts on time and at a reasonable cost |

A great fit for

- ISO 13485 programs (implants, instruments, dental)

- Tight geom/tolerance work with DFM collaboration

- Bar-stock families with repeat features & PPAP/FAI

Not a fit for…

- Non-U.S. sourcing requests

- Sand/Investment cast, sheet-metal, or large weldments

- Same-day emergency builds

7 Citizen A20 VII – 3/4″

3 Citizen A20 VII – 1 1/4″

9 Citizen K16 (Types K16 VII, K16E) – 5/8″

7 Citizen L12 – 1/2″

10 Citizen L20 (Types IX, VII, X) – 3/4″

3 Citizen L32 Type XII – 1 1/4″

42 Citizen M16 (M16, Y-axis, Y&B Axis) – 5/8″

19 Citizen M20 (M20, Y-axis) – 3/4″

35 Citizen M32 (M5-32, Y-axis, Y&B-axis) – 1 1/4″

2 Citizen D25 (Y-axis, B-axis) – 1″

2 Eurotech 420SLLY – 1 3/4″

9 Eurotech B465 (T3-Y3, T2/Y2, SY2) – 2 3/4″

1 Eurotech B436-Y2 Rapido – 1 3/8″

2 Hardinge GT – 1 3/4″

1 Miyano BNX-51MSY – 2″

1 Miyano BNA-42DHY – 1 5/8″

4 Star SB20R IV – 3/4″

10 Star SR10-J – 3/8″

3 Star SR-10J Type C – 3/8″

2 Star SR20R IV – 3/4″

9 Star SV20 – 3/4″

1 Star SW12-R11 – 1/2″

3 Star SW20 – 3/4″

12 Tornos Deco & EvoDeco 10 – 3/8″

4 Tornos EvoDeco 16 – 5/8″

1 Tornos SwissNano 7 – 1/4″

(9) 14″ O.G.P. Optical Comparators with DRO

4 CCP CC-14 Optical Comparators

16 Surface Plates with Height Gauges

800+ Assorted Micrometers, Dial Micrometers, Pin Gauges

6 Mitutoyo profilometers – (surface roughness measurement) Model SJ400

30 Nikon SMZ645 Microscopes 8X to 50X

1 O.G.P. Programmable Smart Scope Video Coordinate Measuring Machine

1 Mitutoyo RA-400 Roundness & Cylindricity checker

3 Mantis Magnified Viewers

1 Oasis Core Inspection System

3 Oasis CoreX2 Inspection Systems

1 Hommel Opticline

2 Keyence IM-6601E

1 Keyence IM-7020

3 Tesa 730063 6 Universal K1-10

3 Universal K2-10

1 Mitutoyo SV3100H4

8 Mitutoyo TM-505

20 Drill Presses 1/2″ Capacity with Production Tables

2 Nichols Production Horizontal Milling Machines, 5HP

2 Hardinge HC Chuckers

2 Sweco Vibratory Finishing Machines

1 Giant Finishing Vibratory Machine

1 Through 5-Gallon Capacity

1 Sunnen Production Hone

4 Hardinge Speed Lathes

1 IFP KP150 Ultrasonic Cleaning Machine

1 IFP KP50 Ultrasonic Cleaning Machine

2 Kennametal C-250 Thermal Deburr Machines

1 Haas CNC Mill

1 Lewis 3024-SH Ultrasonic Cleaner

6 Trinco Blasters

3 Clemco Blasters

1 Comco Microblaster

Parts Maker® CAM for Swiss-type CAD/CAM Software

Esprit CAM Programming Software

Ultra-Edit Code Editor Software

SolidWorks Premium CAD Software

Cimlinc Software

ISO 9001:2015

ISO 13485:2016

ITAR

2 Bridgeport Model J Vertical Milling Machines

2 14″ x 40″ Tool Room Lathes

2 Brown & Sharpe 6 X 18 Surface Grinders

7 Agathon Diamond Wheel Tool Grinders

1 Haas CNC Mill

1 In-house Citric Passivation ASTM A967

1 Twin Robot Vision Guided Secondary Preparation Cell

1 Kennametal C-250 Thermal Deburr Machine

1 Extrude Hone Thermal Deburr Machine

1 iFP High Volume Vacuum Chamber Parts Washer (mod. alcohol or solvent, + dry RP) (KP150 & KP50)

Contact Us

Tell us a bit about your project and we’ll get back the same business day.

Connect with a Sales Rep

Prefer a direct line? Reach out anytime.

I can get you in direct contact with our engineering team or assist with any additional questions you may have.

Thanks — we’ve got your message.

Expect a response in a couple of hours (business hours). If it’s urgent, call 540-589-7888.