Jackson Spring

ISO 9001 • IATF 16949

Line Card

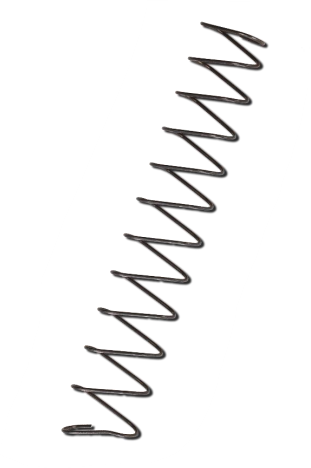

Compression

- Wire Range .2mm to 12.0mm

- Closed ends not ground

- Closed ends ground

- Open wound

- Conical, Cylindrical, Hourglass, Barrel

- Variable pitch

Extension

- Wire Range .25mm to 6.0mm

- Close wound

- Rarely open wound

- Style of loops

- Crossover, German/Machine, Extended hooks, side loops

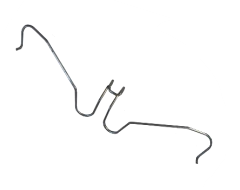

Torsion

- Wire Range .25mm to 6.0mm

- Infinite number of Special Shaped End Configurations

- Straight leg Torsion

- Hook

- Hinge / Crossbar

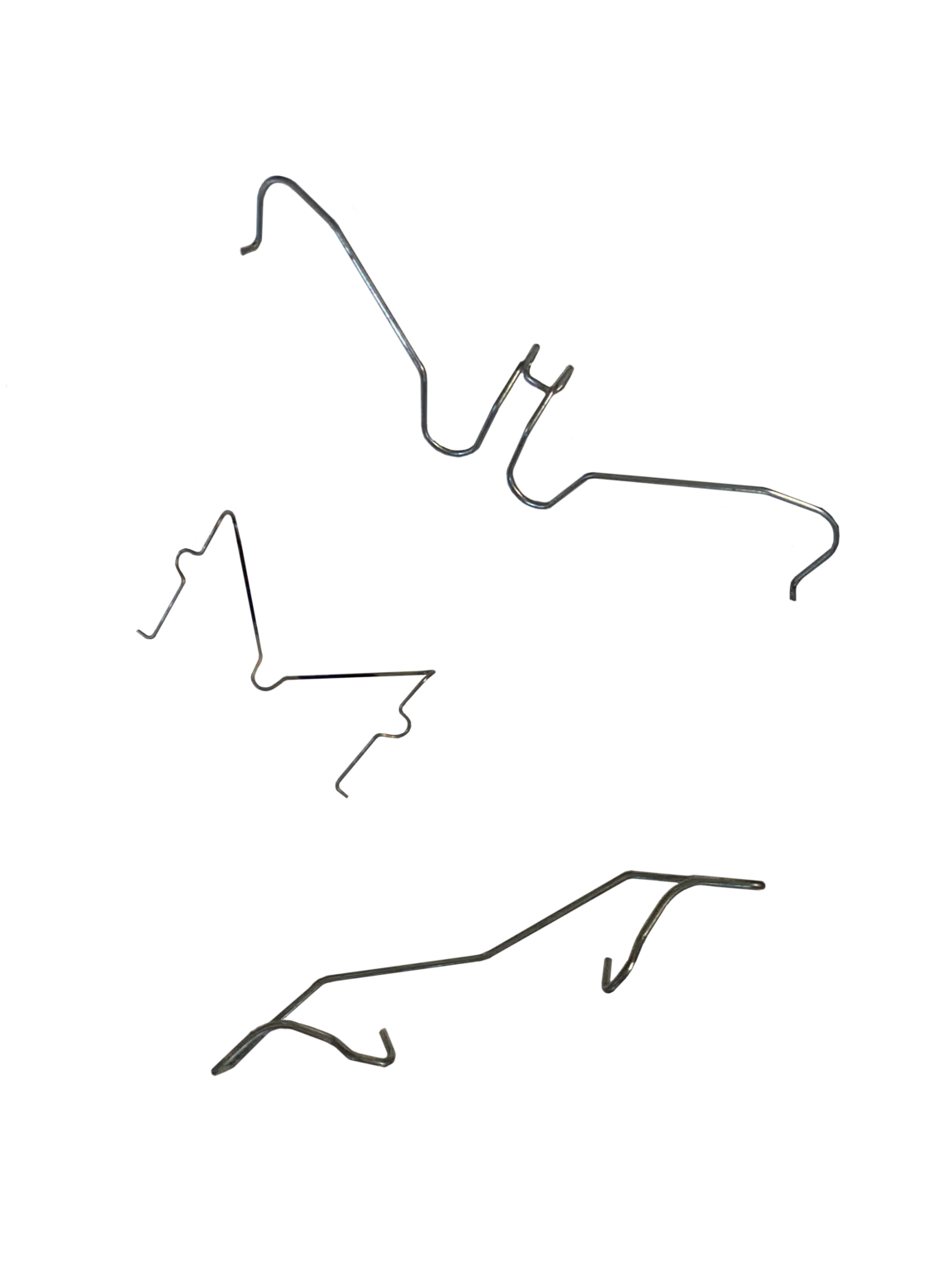

Wireforms / Fourslide

- Wire Range .2mm to 6.0mm

- Multitude of shapes

| Materials | Music Wire, High Tensile Music Wire, Rocket Wire, Missile Wire, Pre-plated Music Wire, Stainless Steel (302/304/316/17-7), HDMB, Oil Tempered, Oil Tempered Chrome Silicon, Valve Quality Chrome Silicon, Phosphor Bronze, Inconel, Basic Wire, Rocket/Missile Wire, 3 Strand Wire, Other Materials Available Upon Request |

|---|---|

| Wire diameters | 0.008–0.312 in (0.20–7.9 mm) typical |

| Part envelope | OD to ~6 in typical; lengths to ~24 in (broader on review) |

| Typical tolerances | OD ±0.005 in • Free length ±0.010 in • Rate/force per print or DIN/ASME; tighter bands on review |

| Volumes / MOQs | Prototype → multi‑million per year |

| Lead times | NPI 2–4 weeks • Production 4–8 weeks (expedites when releases permit) |

| Secondary ops | End grind, stress‑relief, heat treat, shot‑peen, plating/coatings, assembly |

| QA / Documentation | ISO 9001, IATF 16949 • PPAP L1–L3 • FAI • C of C • Traceability |

A great fit for

- PPAP/FAI-driven programs (auto/industrial/defense)

- Tight cycle-life/load requirements with DFM collaboration

- Multi-family spring programs (shared tooling strategies)

Not a fit for…

- Catalog/no-print commodity purchases

- Non-domestic sourcing requests

- Same-day emergency builds

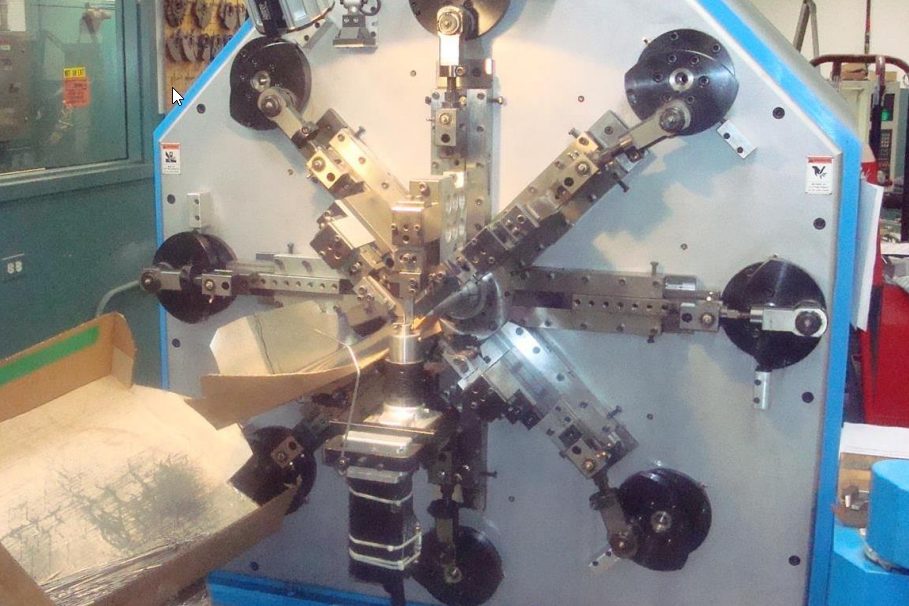

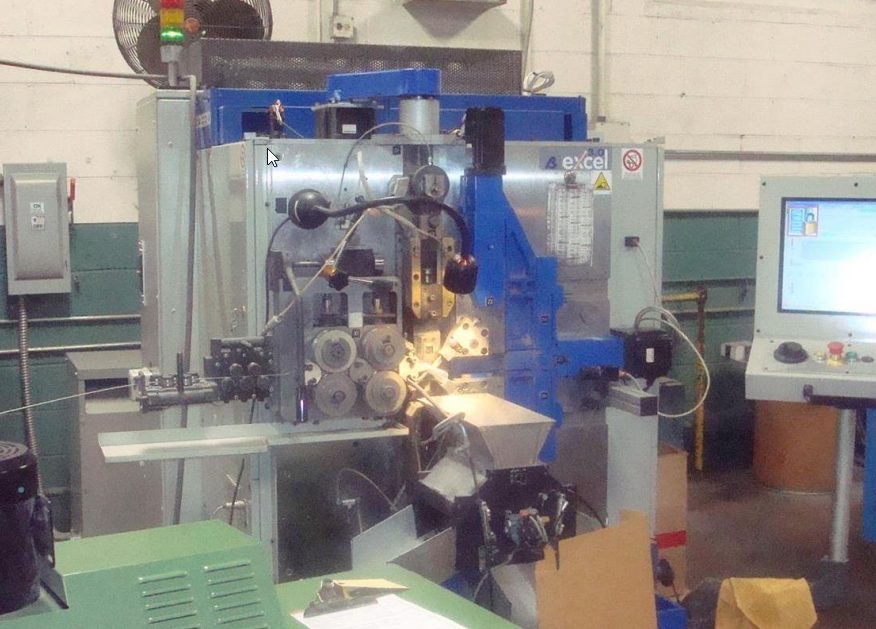

40+ CNC Wire Formers

10 Mechanical Wire Formers

45+ CNC Coilers

4 Mechanical 4-Slide Machines

20+ Spring Grinders

Shot Peening

E coating

Magni Plating

Black Oxide Plating

Chrome Plating

Powder Coating

Phos and Oil

Electroless and Electrolytic

Plating

PTFE Plating

Electropolishing

Magnetic Inspection

And many other types of Plating

Agriculture

Automotive OE & Aftermarket

Firearm

Healthcare

Industrial Valve

Lawn & Garden

Medical

Military

Rotary Sealing

Safety & Relief Valve

Spring Industry

Truck

Grinding

Welding

Color Coating/Painting

Passivation

Tumbling

Stress Relieving

Assembly

Kitting

Cycle Testing

3D Printing

PPAP Services

Full Spring Quality Lab Inspection

IATF 16949:2016

ISO 9001:2015

DFARS Compliant

ITAR

FFL

Contact Us

Tell us a bit about your project and we’ll get back the same business day.

Connect with a Sales Rep

Prefer a direct line? Reach out anytime.

I can get you in direct contact with our engineering team or assist with any additional questions you may have.

Thanks — we’ve got your message.

Expect a response in a couple of hours (business hours). If it’s urgent, call 540-589-7888.